Carbonation is one of the leading mechanisms of deterioration of reinforced concrete bridges worldwide. In fact, more than 15 years ago, the EU-funded BRIME project identified that highway bridges in France, the UK, and Germany presented deficiencies at rates of 39%, 30%, and 37%, respectively, with the main cause being the corrosion of reinforcement, a process in which carbonation plays a key role.

Carbonation is a current and growing problem, given the current climatic situation together with the high level of ageing of bridges in Europe. In fact, according to future climate forecast reports, the durability of reinforced concrete structures will be more affected as the concentration of CO2 in the atmosphere increases. Thus, we find that the impact of this problem is significant enough that it has even been the cause of bridge collapses such as the Morandi Bridge in Genoa (Italy) in 2018.

The presence of additional pathways for CO2 penetration, such as cracks or construction defects, enhances carbonation as it facilitates and accelerates the diffusion of external agents and can combine with these problems to cause even greater structural damage. Therefore, any bridge is susceptible to be potentially affected by this phenomenon.

Only early detection and understanding of carbonation progression can ensure the long-term integrity and performance of concrete structures. However, given the limitations of visual inspection, engineers face the challenge that this phenomenon is not easily detectable, which can lead to catastrophic situations.

What is carbonation?

Carbonation is a chemical process in which carbon dioxide (CO2) found in the air is dissolved at the surface of the concrete and reacts with the calcium hydroxide (Ca(OH)2) from the hydrated cement paste to form calcium carbonate (CaCO3). As carbonation progresses, the pH inside the concrete gradually decreases, leading to a decrease in alkalinity.

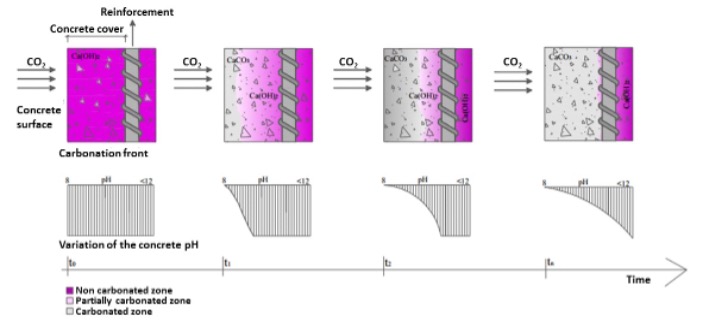

Carbonation itself does not degrade the strength of the concrete. However, it decreases the alkalinity of the concrete and, thus, depassivates the steel reinforcement; once the protective layer is destroyed, the steel reinforcement will be corroded easily. More specifically, the carbonation reaction begins at the concrete surface progressing internally over time, as shown in the figure below.

Advance of carbonation front vs pH reduction in concrete (Possan, E., 2010)

When the carbonation front reaches the steel depth, the corrosion progression phase begins, having caused some changes but no actual damage to the structure to this point.

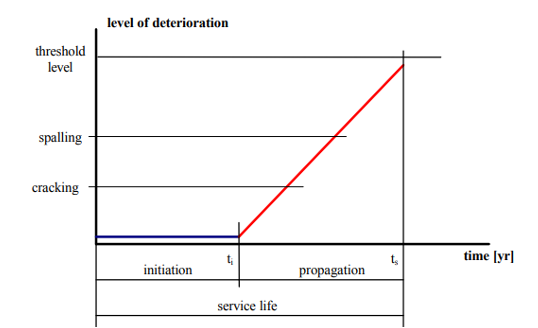

As presented in the figure below, the corrosion process is usually divided into two stages, namely the initiation and propagation stage.

- During the corrosion initiation stage aggressive agents are transported through the protective cover concrete layer by means of various mechanisms such as diffusion, permeation, sorption and migration.

- The corrosion propagation stage starts when these aggressive agents have reached the reinforcement and have caused the depassivation of the steel. This leads to an electrochemical oxidation reaction that reduces the area of the reinforcement and yields products of increased molecular volume, causing the weakening of the steel and spalling of the concrete.

Conceptual deterioration model showing the stages during the service life of a reinforced concrete structure with respect to reinforcement corrosion (Gulikers, J., 2002)

The concrete expansion due to formation of corrosion products results in the cracking of concrete cover. This occurs when the stresses induced by the increasing layer of corrosion products exceed the tensile strength capacity of concrete, especially in structures with small concrete covers as is certainly the case of bridges built before World War II, which are characterised by having small cover depths.

According to this, we can conclude that when structural damage due to reinforcement corrosion becomes visible, deterioration is at a late stage, and it may be too late to take any effective preventive or protection measures.

It is important to note that the rate of carbonation of concrete can be affected by a number of factors, such as the quality of cement used, the water-cement ratio, exposure to carbon dioxide, ambient temperature and humidity, as well as other factors like the presence of cracks or construction defects which provide additional pathways for CO2 ingress. Therefore, it is essential to understand and control all these factors during the design, construction and maintenance of concrete structures in order to ensure adequate service life and performance.

How to control the progression of carbonation?

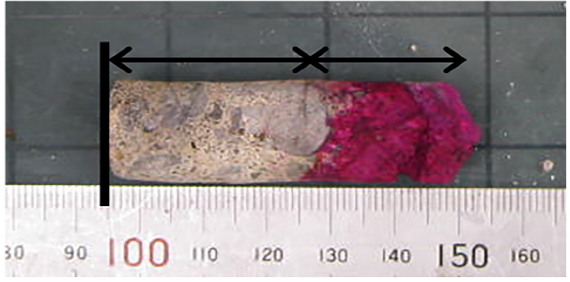

Traditionally, the assessment of carbonation depth is usually performed by a semi-destructive test consisting in spraying a coloured indicator on a core sample extracted from the structure. When the structure is large, this test must be reproduced many times if an assessment of the variability of carbonation depth is required. In this case, the extraction of multiple samples may be technically and economically unfeasible. In addition, this method does not allow detection of the deterioration process at sufficiently early stages.

Measurement of carbonation depth (outer colourless zones) by traditional evaluation (Torrent, R., Imamoto, K. I., & Neves, R., 2020).

Therefore, there is a need to diagnose the depth of carbonation at the earliest possible stage and predict its evolution to avoid the beginning of corrosion progression phase. Only in early stages can carbonation effects be prevented or halted, avoiding the onset of corrosion.

Currently, there is no surface-mounted sensor that can be installed on existing bridges to accurately quantify the depth of carbonation at early stages continuously and in a non-destructive manner. Neither is there any way of accurately predicting the evolution of carbonation and determining what the global influence within a specific bridge structure might be.

However, IDVIA, through its innovative SHM technology for the structural health diagnosis of bridges, has been able to prove something that has also been confirmed by recent international research, which is the fact that corrosion and carbonation at advanced stages of development can be detected through this approach.

The technical explanation for this is that when a high degree of carbonation is presented, there is a change on the natural frequencies of reinforced concrete structures. The main reason for this phenomenon is the increase in mass due to concrete carbonation that leads to a decrease in natural frequencies as carbonation depth increase.

Carbonation also affects the porosity of the concrete. A decrease in natural frequencies owing to an increase in mass due to concrete carbonation is inevitably associated with a decrease in the porosity of the concrete. As the carbonation front progresses, an increasing number of pores become clogged.

In other words, we propose a sensor technology based on highly advanced mathematical and probabilistic methodologies to identify the occurrence of carbonation.

This technology incorporates different functions, allowing to identify the occurrence of carbonation at the earliest stages, much before corrosion initiation, to accurately locate it and also predict the evolution of this deterioration related to the durability of concrete in order to incorporate it into a global structural health system for diagnosis, risk assessment and decision-making for predictive maintenance of bridges.

Our opinion as experts

Carbonation is definitely one of the main causes of steel corrosion in reinforced concrete structures, which can risk their long-term strength and durability.

Due to the significant climate change we are facing, with the corresponding increase in carbon dioxide, reinforced concrete has been shown to deteriorate more quickly. Carbonation of concrete, a phenomenon caused by the penetration of atmospheric CO2 into the concrete, is becoming an increasingly important detrimental factor for bridges with this material in their structural elements.

There is an urgent need to focus more attention on this issue because it is the only way to avoid high repair costs and even catastrophic collapses of bridges. It is clear that a visual inspection is not sufficient to anticipate this phenomenon, which, if overlooked in the inspection, can be catastrophic.

Our innovative advanced SHM technology allows us to validate and calibrate numerical models of the bridge under analysis, providing a real-time diagnosis of its structural health, identifying possible pathologies such as carbonation even in its early stages.

This provides the infrastructure manager with relevant information to make the right decisions at the right time, as well as a structure control and future prediction tool.

References

Aguiar, J.B. & Júnior, C. (2013). Carbonation of surface protected concrete. Construction and Building Materials, 49. 478-483.

Basheer, L., Kropp, J. & Cleland, D.J. (2001). Assessment of the Durability of Concrete from its Permeation Properties: A Review. Construction and Building Materials, 15(2-3), 93–103.

BRIME. Deliverable D14 Final Report. (2001). Disponible online: https://trimis.ec.europa.eu/sites/default/files/project/documents/brimerep.pdf

Chinchón-Payá, S., Andrade, C., & Chinchón, S. (2016). Indicator of carbonation front in concrete as substitute to phenolphthalein. Cement and Concrete Research, 82, 87-91.

Gulikers, J. (2002). Critical review of corrosion deterioration models for reinforced concrete. Proceedings of the 9th Durability of Building Materials and Components (DBMC’02), 17-21.

Papadakis, V., Vayenas, C. & Fardis, M. (1991). Physical and chemical characteristics affecting the durability of concrete. ACI Materials Journal, 88(2), 186–196.

Possan, E. (2010). Modelagem da carbonatação e previsão de vida útil de estruturas de concreto em ambiente urbano”, Tese de Doutorado em Engenharia, Programa de Pós-Graduação em Engenharia Civil, Universidade Federal do Rio Grande do Sul, Porto Alegre.

Talukdar, S. (2013). The effects of global climate change on carbonation induced corrosion of reinforced concrete structures. Doctoral dissertation, University of British Columbia.

Tayta Construcciones. (2022). https://www.taytaconstrucciones.com/2022/05/28/como-evitar-la-corrosion-del-fierro/

Torrent, R., Imamoto, K. I., & Neves, R. (2021). Resistance of concrete to carbonation and chloride penetration assessed on site through nondestructive test. Structural Concrete, 22(5), 2581-2594.

Villani, P. (2019). Dynamics and causes of the collapse of the Morandi viaduct in Genoa. Session 30: Damage Assessment on Bridges.